Face Mask Nose Wire Head Strap Ear Band Welding machine

Working principle of ultrasonic mask spot welding machine:

1.Ultrasonic welding machine, also known as ultrasonic plastic welding machine, is to transmit ultrasonic waves to the plastic processing parts through the welding head, so that the two plastic joint surfaces are subject to intense friction due to the effect of ultrasonic waves. Join.

This technology has the advantages of fast speed, strong welding, etc. More importantly, it can automate the processing of plastic products. Ultrasonic plastic welding machine can perform plastic welding, implantation, forming, riveting, cutting, sewing and other operations,

only need to change the welding head can be used for a variety of applications, including plastic butt welding, metal screw implantation, riveting, point Welding, forming, cutting, etc.

2.Compared with traditional processes (such as adhesive bonding, ironing or screw fastening, etc.), ultrasonic spot welding has obvious advantages of high production efficiency, good welding quality, environmental protection and energy saving.

Hand-held ultrasonic welding machine can also be used for welding, riveting of thermoplastic plastic products, as well as inlay and blanking process between metal parts and plastic parts. It has completely replaced the process of pasting organic melting point agents.

It has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, firm welding, and easy operation.

3.Ultrasound can not only be used to weld metals, hard thermoplastics, but also fabrics and films. The handheld ultrasonic welding machine can replace different ultrasonic welding heads according to the size of the riveting point of the product to be welded and the welding requirements,

which is fast and convenient, and the cost is much lower than that of the special automobile door ultrasonic welding machine, which meets the needs of customers.

Specification:

| Model | DZ-8833 |

| Voltage | 220V/50Hz; 110V/60Hz (Can be customized) |

| Output power | 2000W |

| Packing size | 126*60*126cm |

| Weight | 110kg |

| Efficiency | 60times / minute |

| Suitable material | All kinds of woven belts, magic tape, laces, zippers, trademarks, various leather materials and other belts. |

Features:

1. Speed up to 100 times per minute.

2. PLC touch screen operation, automatic counting.

3. Automatic tape edge sealing, no scorching, no blackening, no burrs.

4. Automatic cutting, saving labor, one person can operate multiple machines.

5. Rotary design of the knife holder, the angle of the cutter can be adjusted freely.

6. The cutting mold die can be exchanged arbitrarily, it can cut tape with straight angle,

oblique angle, dovetail edge, and round edge. Also the installation is simple and convenient.

Our Services

Company Information

1.Are your company a trading one or a factory ?

Factory + trade (integration),10 years focusing on test instruments field,3 years exporting experience.

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of test you

need to do and the required specification.

3.What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20

working days after deposit receipt. If you are in urgent need, we can consider making special

arrangement for you.

4.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to

your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

5.Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to

arrange hotel and pick up you from airport.

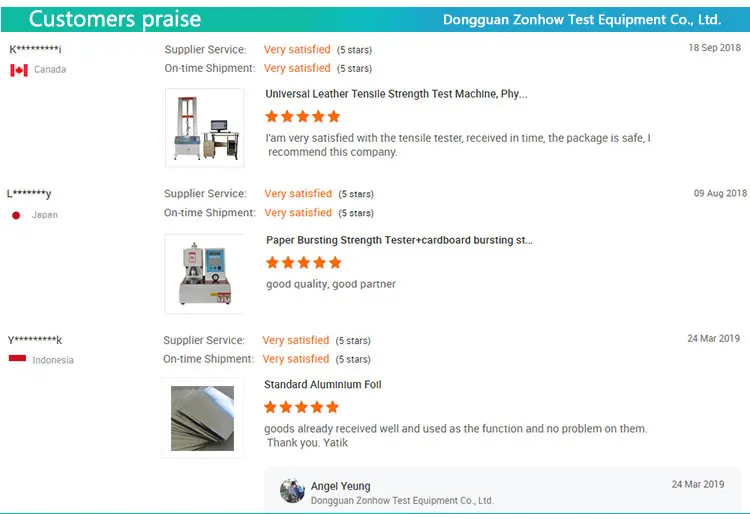

6.Do you have customers of our country before?

Now our testing machines have been sold to more than 26 countries, like USA, Canada, Russia,UK,

Italy, Germany, European Union, India, Pakistan, Philippines, Singapore, Thailand and Vietnam,Iran,

Brazil and so on.

7.How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and

part parts change, necessarily, our engineers may go to your place for better service.

8.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many

testing machines abroad by sea or by air without damage.

9.What is the order process?

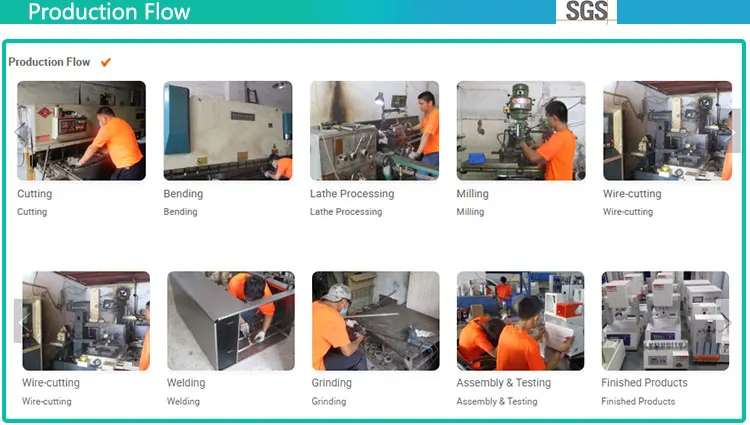

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and

debugging - balance payment - packing - delivery - customer receiving - after service.

10.How to install and use the product

The product is shipped with an operating instructions and video of English version.