IP Class Rain Test Chamber, Rain Spray Simulation Environmental Tester

Summary:

IP Class Rain Test Chamber is used to simulating the lighting , auto parts , household appliances and other products in condition of moisture or rain , to see the influence of water to the products. Through this can test the resistance to the rain penetration and moisture proof ability of products.

Rain spray testing through a rigorous scientific design, making it can realistically simulate dripping rain, splashing water , water spray and other environment. It uses advanced controlling system and inverter technology , making the rotation angle of the specimen frame, the swing angle of the oscillating bar and the water swing rate can be automaticallyadjusted.

Features:

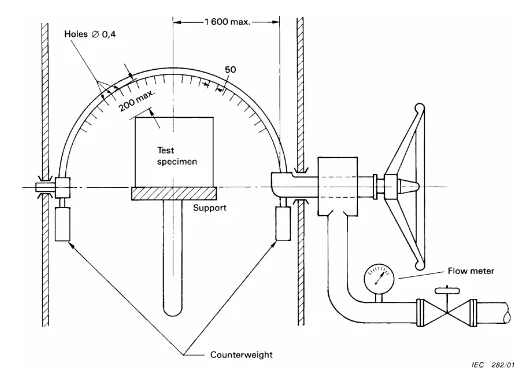

1. Comply with requirement of IEC60529 standard IPX3 water pouring test and IPX4 water splash test.

2. The test sample will be put or installed on the center of the half-round sinuous pipe and make the bottom of the test samples and the oscillating axis in a horizontal position. During test, the sample would spin around the center line.

3. Can manual default the test parameters, complete testing automatically shut off the water supply and pendulum pipe angle automatic zeroing and automatic eliminate seeper, avoid scale blockage needle tip.

4. Inner case’s material is imported steel plates; shell is made of #304 stainless steel.

5. Water pressure and flow rate adjustable.

6. Unique sprinkler can stably control the rain quantity and pressure.

Structure of IP Class Rain Test Chamber, Water Spray Resistance Chamber

The outside layer is composed of the high quality stainless steel plate, the inner container is the composed of stainless steel tabula rasa.

Large area of visible glass door, easy to observe the test specimens in the testing chamber

The button is made of high quality of tank, can be fixed PU activities wheel, it is convenient for user moved.

With 270 degree swing pipe & 360 degrees whorl pole water jet device.

Adjustable speed samples stage.

Control System:

(Germany) admiralty. Per stig moller programmable controller to complete the contrl of the whole system of time and sequence.Adopt imported frequency converter speed effectively guarantee the test according to the standard operation.Equipped with water filter.

Specifications:

ip class water/rain spray resistance test chamber

IPX1/2 Vertical Rain Drop Test

1. Meet the requirement of IEC60529 standard IPX1 vertical rain drop test and IPX2 15°inclination rain drop test.

2. Rainfull capacity: IPX1: 1 ±0.5mm/min IPX2 : 3 ±0.5mm/min

3. Water drop chamber effective droping area: 1000*1000mm, water droping hole diameter: Φ0.4mm, hole distance: 20*20mm

4. Water drop chamber uses vaccum design, match with oxidation alloy aluminium and high rust stainless steel material structure, nozzle contact a brass tapered design, convenient in installation and replace needle tip.

5. Rain drop device can automatically lift, nozzle is located in 200mm from the highest point of test sample, and equipped with protection devices to ensure it would not drop too fast. It can also lift manually.

6. With compressed air dry function, when the experiment is complete but will drop out the excess water clean, avoid long time water dirty jams needle tip.

7. Dc electric lifting motor drive, stainless steel wire rod, pulley guide with locking nut lifting device.

8. Aluminum alloy and stainless steel fuselage; Hang to the wall or four column equality lifting.

IPX3/4 Vertical Rain Drop Test

1. Meet the requirement of IEC60529 standard IPX3 water pouring test and IPX4 water splash test.

2. The test sample will be put or installed on the center of the half-round sinuous pipe and make the bottom of the test samples and the oscillating axis in a horizontal position. During test, the sample would spin around the center line.

3. Swing pipe standard configuration: R600mm and R1000mm two types. Swing pipe inner diameter: Φ15mm.

4. DillΦ0.4 holes and make the water spray to the center. The water pressure of the device entrance is equal to 10m water level, spraying water pressure is 80-100kpa.

5. Water spraying pipe swing angle: 120º,180º,360º, Vertical sides: 60º,90º,175º. Complete a swing(2*120º) time is 4S. Complete a swing(2*360º) time is 12S.

6. Can manual default the test parameters, complete testing automatically shut off the water supply and pendulum pipe Angle automatic zeroing and automatic eliminate seeper, avoid scale blockage needle tip.

7. ip class water/rain spray resistance test chamber Use Mitsubishi PLC, LCD panel test procedure control box, stainless steel curved pipe, alloy aluminum frame, stainless steel shell.

8. Servo drive mechanism, guarantee the pendulum pipe Angle of precision, the overall pendulum tube structure for hang a wall.

1.Are your company a trading one or a factory ?

Factory + trade (integration),10 years focusing on test instruments field,3 years exporting experience.

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of test you

need to do and the required specification.

3.What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20

working days after deposit receipt. If you are in urgent need, we can consider making special

arrangement for you.

4.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to

your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

5.Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to

arrange hotel and pick up you from airport.

6.Do you have customers of our country before?

Now our testing machines have been sold to more than 26 countries, like USA, Canada, Russia,UK,

Italy, Germany, European Union, India, Pakistan, Philippines, Singapore, Thailand and Vietnam,Iran,

Brazil and so on.

7.How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and

part parts change, necessarily, our engineers may go to your place for better service.

8.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many

testing machines abroad by sea or by air without damage.

9.What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and

debugging - balance payment - packing - delivery - customer receiving - after service.

10.How to install and use the product

The product is shipped with an operating instructions and video of English version.